Spiral Classifier & Dewatering Screw

The dewatering screw use removes the slurry particles from the waste stream before the retention pond, which allows for no tailing to enter the retention pond and optimizes retention pond supply in places will less water access. The spiral classifier use case separates out the smaller waste particles from the ore processor tailings allowing the larger particles to be recirculated to liberate more values.

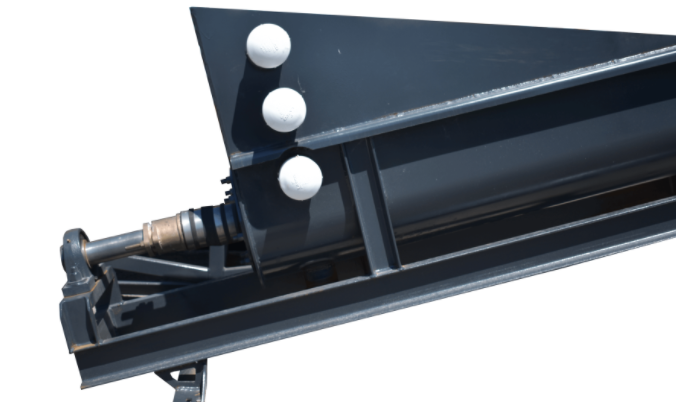

The size of the particles discharged to the tailings pond is managed by two primary methods. First, the volume of the feed water can be adjusted to flush the pool at the bottom of the classifier. More water means a coarser particles discharge to the tailings pond. The second adjustment is the proper height setting of the water level in the classifier pool. Please reach out to one of our experts to get details on the three outlet ports along the side of the pool (at different elevations) and when to choose the upper vs lower ports.