Concentrators

Processing capacity of 350 lbs to 60 tons per hour

Best-In-Show Gravity Concentrators

Our GSI centrifugal gravity concentrators replace all conventional gravity recovery equipment such as sluices, jigs, cones, and spirals for fine gold and other metals and minerals. GSI’s concentrators are primarily used for alluvial placer mining, dredging, prospecting, bulk sampling, and hard rock mining and tailings recycling.

- 24 Hour Shifts: Can concentrate for up to 24 hours without a required clean-out securing the gold for an entire shift

- Durability: Built-in North America with stainless-steel laser-cut bowl that can withstand the most severe mining conditions

- High Recoveries: Averages an additional 20% more yield when added to a standard sluice operation

-

| Optimal Capacity |

Screen Size |

No. of Motors |

Motor Horsepower |

Water Required |

G-Force |

| 350lbs/hr |

4mm |

Two |

One 1/10 HP & One 1/4 HP |

30GPM @ 35PSI |

80 G |

| 6TPH |

6mm |

One |

3/4 HP |

60GPM @ 35 PSI |

70 G |

| 6TPH (portable) |

6mm |

Two |

One 1/4 HP & One 3/4 HP |

60GPM @ 35 PSI |

70 G |

| 30TPH |

6mm |

One |

7.5 HP |

115 GPM @ 35 PSI |

70 G |

| 60TPH |

6mm |

One |

25 HP |

310 GPM @ 35 PSI |

70 G |

350 lbs/hr

Size: 7 inch (178mm)

6 tph

Size: 12 inch (305mm)

6 tph

Size: 12 inch (305mm)

30 tph

Size: 21 inch (533mm)

60 tph

Size: 40 inch (1016mm)

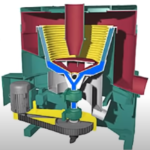

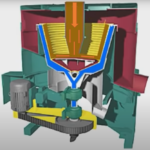

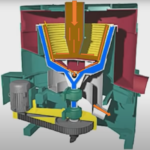

How it works

Water enters the rotating concentrate cone through a series of fluidization holes. Feed slurry then enters through the stationary feed tube and into the concentrate cone.

When the slurry reaches the bottom of the cone, it is forced outward and up the cone wall under the influence of centrifugal force.

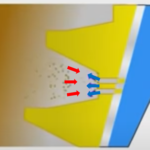

The slurry fills each ring to capacity to create a concentrating bed. The flow of water injected into the rings is controlled to optimize bed fluidization.

A constant flow of water is injected into the rings (seen in blue). High specific gravity particles are captured and retained in the concentrating cone (seen in red).

Upon finishing the concentrate cycle, concentrates are flushed from the cone into the concentrate launder through the multi-port hub.