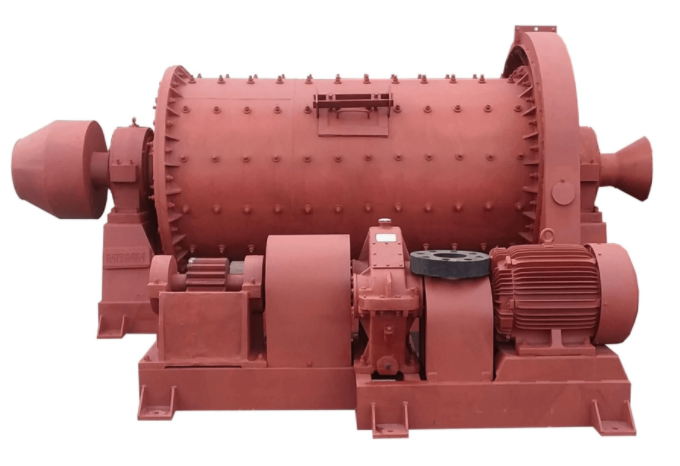

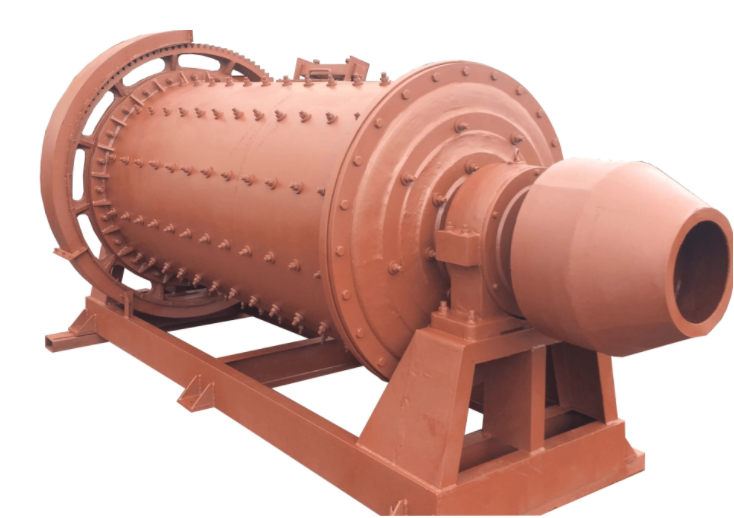

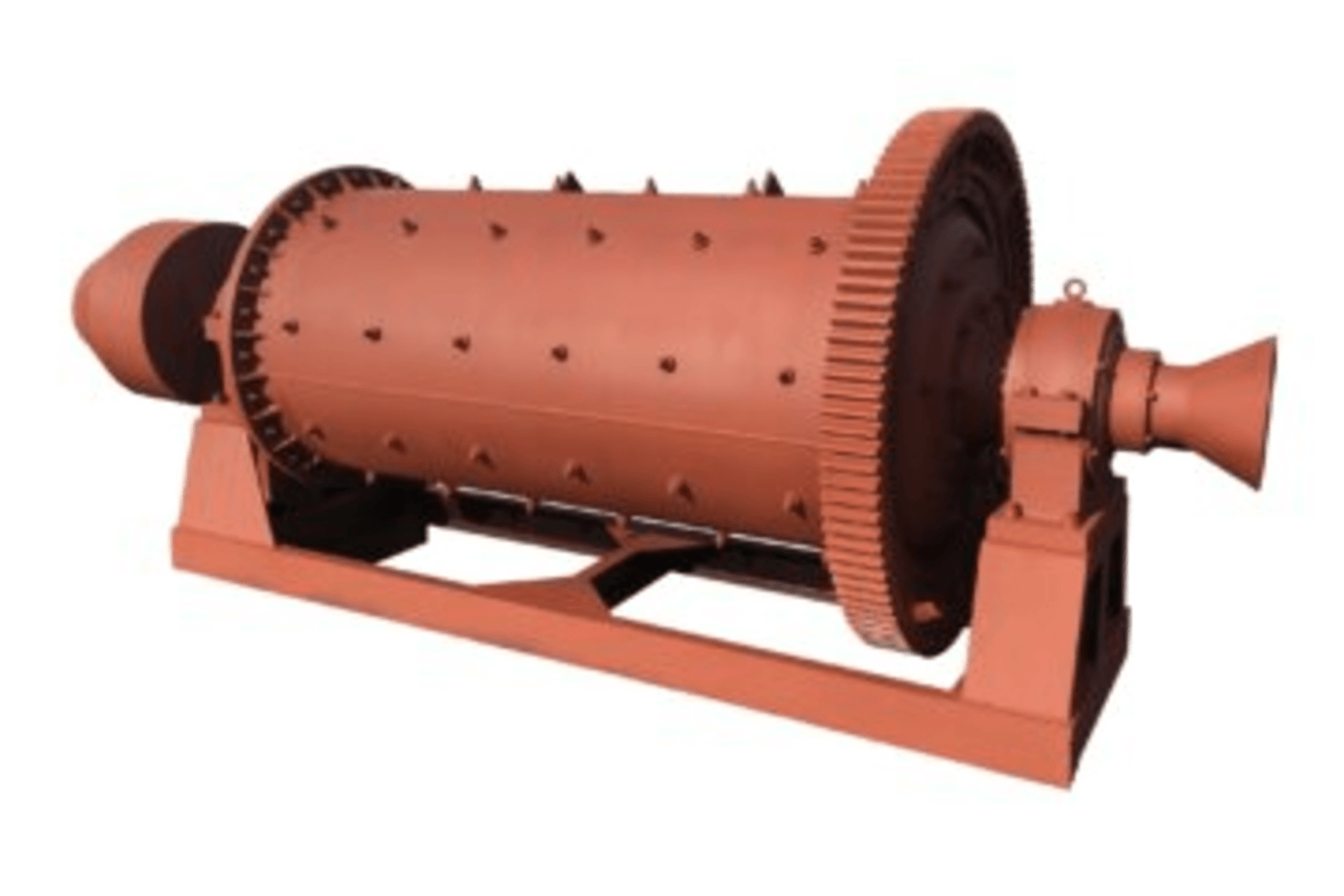

Ball Mills

Processing capacity of 272 kilos to 50 tons per hour

Industrial-Grade Ball Mills

Ball mills play a primary role in traditional hard rock grinding and are ideal for reliable, continuous long-term operations. GSI’s ball mills are housed with oversized roller bearings and a complete drive system discharging mesh sizes from ~40M to <200M.

The capacity, or throughput, of our GSI ball mills are directly linked to the particle size of the ball mill discharge. For instance, it is roughly 3 times as fast to reach a 65 mesh grind than a 200 mesh grind. Contact our mining experts to design and engineer the optimal grinding circuit and establish a proper commercial liberation size.

All wear parts are highly abrasion resistant & replaceable

Thick, manganese steel bolt-in liner sections

Oversized trunnion bearings for long life

1”, 2”, 3”, and 4” diameter alloy balls included

Includes discharge trommel, allowing a choice of screens to limit top size discharge

Capacities of GSI ball mills based on quartz ore

-

| Approx U.S measure (ft) |

Diameters & Length (mm) |

Total lbs weight with no balls |

Lbs weight of balls |

Total lbs weight w/ mill, drive, & balls |

ZD Motor HP |

| 3×6 |

9,460 |

4,224 |

13,684 |

13,684 |

20 |

| 4×8 |

23,100 |

33,220 |

33,220 |

33,220 |

40 |

| 5×10 |

38,500 |

59,400 |

59,400 |

59,400 |

100 |

| 9.5×14 – 11.5×17 – 13×21 |

Variable |

Variable |

78,000 |

Variable |

1000 |

To grind 12 mm input to 65 mesh output

-

| Average capacity (t/h) |

Liters/min water

flow |

Ball sized- equal weights, all sizes |

| 0.9 |

42-59 |

2-4” |

| 2.3 |

54-82 |

2-4” |

| 4.6 |

108-214 |

2-4” |

| 50 |

Variable |

1-3″ |

To grind 12 mm input to 100 mesh output

-

| Average capacity, (t/h) |

Liters/min water flow |

| 0.6 |

40-57 |

| 1.7 |

51-78 |

| 3.9 |

102-204 |

| 40 |

Variable |

To grind 12 mm input to 200 mesh output

-

| Average capacity, (t/h) |

Liters/min water flow |

| 0.3 |

38-55 |

| 0.8 |

48-75 |

| 1.6 |

96-194 |

| 32 |

Variable |