Mining

Buying single pieces of equipment does not result in the 95% recoveries we promote. Build a custom plant with machinery that is made to work together.

Deign your plant around the ore mineralogy and the expert advice of GSI’s geologists, mineralogists, metallurgists, and mining experts.

We will ensure synergy amount the miners and vehicles, equipment types, sizes, and processing capacities, water flow rates, and much more.

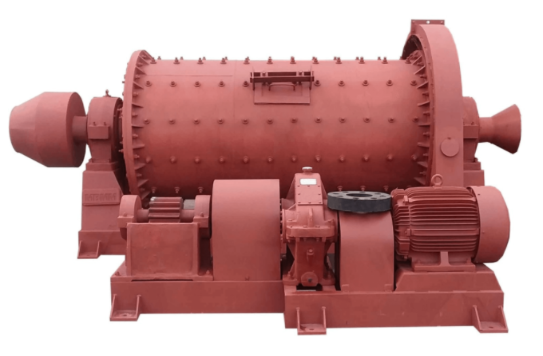

Placer Equipment Overview